Our History

Wespine Industries is a softwood sawmill business, operating at its Dardanup Western Australia site since the early 1980s.

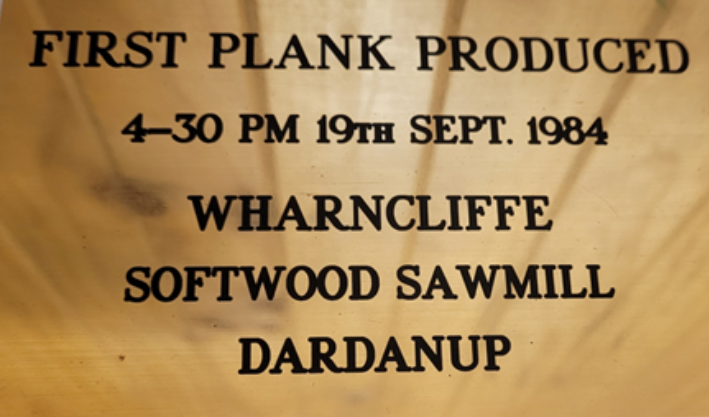

From The First Plank

Native hardwood harvesting and processing was predominant in WA (and much of Australia) well into the 1980s. Up to this time, processing of pine logs was limited to relatively small plywood and sawmill operations.

In the early 1970s, a particleboard mill was established in Dardanup, primarily to process logs from radiata pine thinnings from the southern plantations. In the 1980s, an MDF plant was established in Perth to process both pinaster and radiata thinnings logs. At this time, there were a number of small pine sawmills spread from Perth to Manjimup, but none had the scale to compete with the many global-scale pine operations in North America and Europe. Indeed, none had access to sufficient resource to contemplate expansion to ‘global-scale’ which at the time was roughly defined as a sawlog intake of 400,000 metres cubed (m3 /tonnes) per year.

Wharncliffe was formed in the late 1970’s by a consortium of three forest industries companies: Westralian Forest Industries (Wesfi), Consolidated Pine Industries (CPI) and The Adelaide Timber Company (ATC). The ATC was owned by the Shepherdson family and had milled jarrah for a number of generations. As the availability of jarrah diminished through the early 1980s, Wharncliffe was given access to radiata pine as an alternative to hardwood. As a lead into the softwood industry Wharncliffe purchased a small pine mill on the outskirts of Margaret River in the late 1970’s and began to process 15,000m3 of pine logs per annum.

Early Days

In 1984 the Margaret River mill closed and a new mill was commissioned by Wharncliffe at 241 Moore Road, Dardanup. By this time CPI had withdrawn from the business, leaving a 50/50 joint venture between Wesfi and ATC. In 1985 the ATC businesses were sold and Wesfi purchased its Wharncliffe shares to secure long term access to mill residues (chips, sawdust and trim blocks) for feedstock for the particle board plant located one kilometre from the sawmill on Moore Road, Dardanup. The mill was renamed Wesfi Pine at that time.

In the late 1980s, a number of WA softwood sawmill operators came together to investigate the feasibility of combining resources to build one global-scale softwood sawmill. Various WA Government agencies were involved in the discussions because, without the support of the WA Government and its various agencies, access to sufficient resource (sawlogs) would not have been possible.

The founding joint venture partners included Wesfi Ltd and Bunnings Forest Products, two long-standing WA-based forest products companies. The formation of the joint venture was underpinned by a WA State Agreement which passed through the WA State Parliament and was enacted early in 1992.

The joint venture was incorporated as Wespine Industries Pty Ltd, and which, with strong support from the WA Government, commenced operation at the Wesfi pine mill site on Moore Road in Dardanup West, WA in July 1992.

At the commencement of operations in 1992, the Wespine mill had access to around 140,000 m3 of pine sawlogs annually. Under its agreement with the State, Wespine planned to expand its capacity to over 400,000 m3 p.a. within 20 years (that is, by 2012). Wespine increased its capacity steadily to about 350,000 m3 p.a. by 2002 and to over 400,000 m3 p.a. in 2008.

At the time that Wespine’s expansion was in progress, the industry world-wide was embracing increasingly sophisticated electronic automation. This provided the opportunity for Wespine to dramatically increase its processing efficiencies at the same time as increasing capacity. By the time its capacity expansion was complete, Wespine had improved its efficiencies to world class levels.

Photo: The plaque that was attached to the first piece of timber milled by Wharncliffe on the Dardanup mill site in 1984.

Photo: The Wesfi Pine Sawmill on Moore Rd, Dardanup in the late 1980s.

Photo:

The new Greenmill log break-down line, installed spring 2007.

Photo:

The last ‘conventional’ batch kiln that Wespine built, back in 2003. In 2019, Wespine installed the Continuous Drying Kiln, with far greater energy efficiencies.

Expansion

At the time that Wespine’s expansion was in progress, the industry world-wide was embracing increasingly sophisticated electronic automation. This provided the opportunity for Wespine to dramatically increase its processing efficiencies at the same time as increasing capacity. By the time its capacity expansion was complete, Wespine had improved its efficiencies to world class levels.

In parallel with the expansion of its facilities, Wespine developed markets for its greatly expanded volume of sawn timber products which now approaches four times the quantity sold in 1992. Harvesting and processing of WA hardwoods had been reducing over the years from more than a million tonnes annually to around 250,000 tonnes pa by the early 2000s. Much sawn hardwood had been used in home building in WA, and this has been replaced over time by structural pine products.

Today Wespine’s two shareholders are Wesfarmers Bunnings and The Laminex Group. Wesfarmers purchased the Bunnings group of companies in the late 1990s, and Bunnings Forest Products ceased to trade in 2005 when Wesfarmers sold the last of its hardwood processing interests in WA. Westralian Forest Industries Ltd (Wesfi) sold its shareholding in Wespine in the early 2000s. Since this time the remaining shareholding in Wespine has been held by The Laminex Group who purchased the particleboard mill close to Wespine’s mill together with a 50% share in Wespine. The Laminex particleboard mill consumes all of the wood fibre residues from Wespine’s mill including wood chips, sawdust and planer shavings.

Wespine’s structural softwood products are today regarded as among the best produced in Australia, and Wespine is among the most highly regarded sawmilling companies in the country.